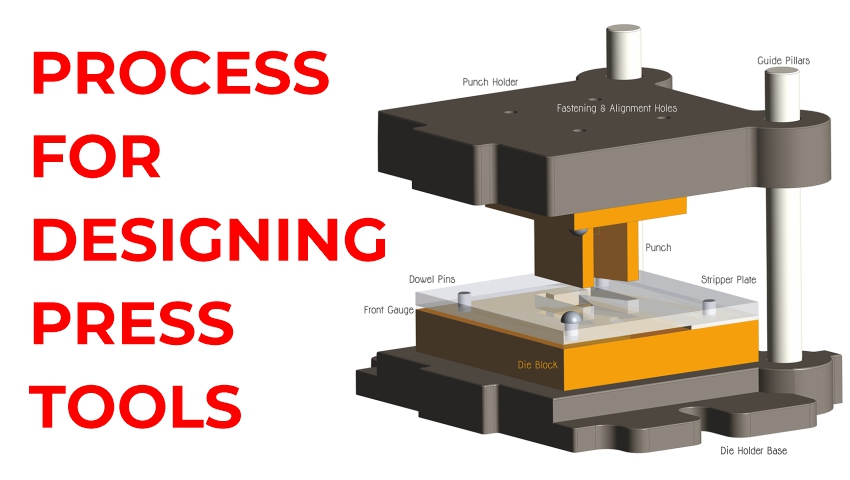

Process for designing press tools

What are press tools?

A press tool is a specialized tool used in manufacturing industries to carry out different manufacturing processes. The press tool is embedded in a press machine and designed to shape or cut metal using force. It is a device by which the sheet metal can be converted into the required shape by various press operations.

Application of press tools

Press tools are used in various applications. It is used to create tools and dies for the mass production of parts from sheet metal. This process is widely used in the manufacturing industry, as it allows for the efficient and mass production of different components. Press tool design involves various techniques, including CAD/CAM software, 3D printing, and traditional machining methods. The application of press tool design can be seen in many industries, from automotive to electronics, medical devices, and more. With its ability to produce complex shapes quickly and cost-effectively, press tool design has become an invaluable asset in modern manufacturing processes.

Factors to consider while designing press tools

Designing press tools requires careful consideration of several factors and it must be considered to ensure that it meets their purpose. By understanding how these factors interact with each other, designers can create a tool that is both effective and safe for use.

Some of the factors are

- Type of sheet material used in press tool design- Different types of materials are considered while designing a press tool and parts, it includes D2, EN31, Mild Steel, D3, high carbide materials, chromium steels, and high-speed steels.

- Size and type of machine tool – It varies in different sizes and they operate using the machining process of hydraulic, pneumatic, and mechanical presses to produce sheet metal components in large volumes.

- Interaction with user – The goal of interaction with the user is to design and create products that enable the user to achieve their objective in the best possible way.

- Function – Functionality of product based on design and material.

- Durability – The product design should not have a catastrophic failure, must be durable, and must withstand all tests conducted

All these factors must be considered while designing a press tool to provide optimal performance.

Press Tool Design Checklist by Vocal Tech Solutions

1. Operations – Before the design process begins, we need to determine the type of operations to be carried and these operations depend on the size, shape, and material of the press tool.

2. Quality check – Involves testing units and determining if they are within the specifications for the final product. The main reason to have a quality check is to determine how close are the dimensions of the product manufactured to the design of that product. We make sure to complete every step to produce high-quality products on time.

3. Parts management – For parts manufactured at a mass scale, management of each part needs to be done to reduce the fluctuations between design and shop floor

4. Build cost calculation – Build cost depends upon the material and the type of manufacturing process carried out. For higher efficiency and tolerance high-quality material and the latest manufacturing process are to be carried out.

Vocal Tech Solutions has been providing design for press tools and provided service-based customer needs, production requirements, and infrastructure. We provide a wide range of Mechanical Design and industrial solutions.

We provide Press Tool Design Services for

- Blank Development

- Forming Tool

- Progressive Tool

- Panel Dies

- Drawing Tool

- Bending Tool

- Compound Tool